Pellets display

Pellet manufacturing is a process in which active ingredients are made into pellets with a diameter of 0.8-1.4mm through a special granulation process. Compared with the simple granulation process, the surface of the pellets is smooth and the coated pellets can isolate the air, humidity, etc. in direct contact with active ingredients.

Why Pellets?

Protection ingredients

Since the pellets are coated with a protective film during the final step of the manufacturing process to prevent damage by gastric acid, making the ingredients into pellet form will protect the active ingredient from loss of activity as it passes through the digestive system. In addition, for some components that are easily oxidized and decomposed, pellets can protect them from contact with air and light.

Nice look and better fluidity

These 0.8-1.4mm diameter balls have a round surface and uniform particle size, and can be customized to add any color. The color is mainly derived from natural pigments and some colored vitamins, such as riboflavin. You know, some ingredients don't flow very well and it doesn't fit easily into the capsule, and the pellets will solve that problem perfectly, and you'll see, it's so beautiful in the clear capsule shell.

Sustained release

The sustained-release effect is a very important benefit of pellets. Just imagine, some functional ingredients, such as analgesic PEA, are consumed at the same dose, the sustained-release pellets can allow the user to feel pain relief that lasts for 8 hours. The effect means that users can eat 1-2 times less in a day, which greatly reduces the dosage and toxicity. Products that promote sleep are also suitable for sustained-release effects, such as GABA. Just imagine, take it before bed and get a full night of high-quality sleep.

Palatability

In the application of functional food, in addition to the aesthetics of pellets, we also have the ability to add more flavors to the coating on its surface, such as vanilla, chocolate and other fruity flavors. This is very effective for masking the odor of some amino acids or some very bitter ingredients.

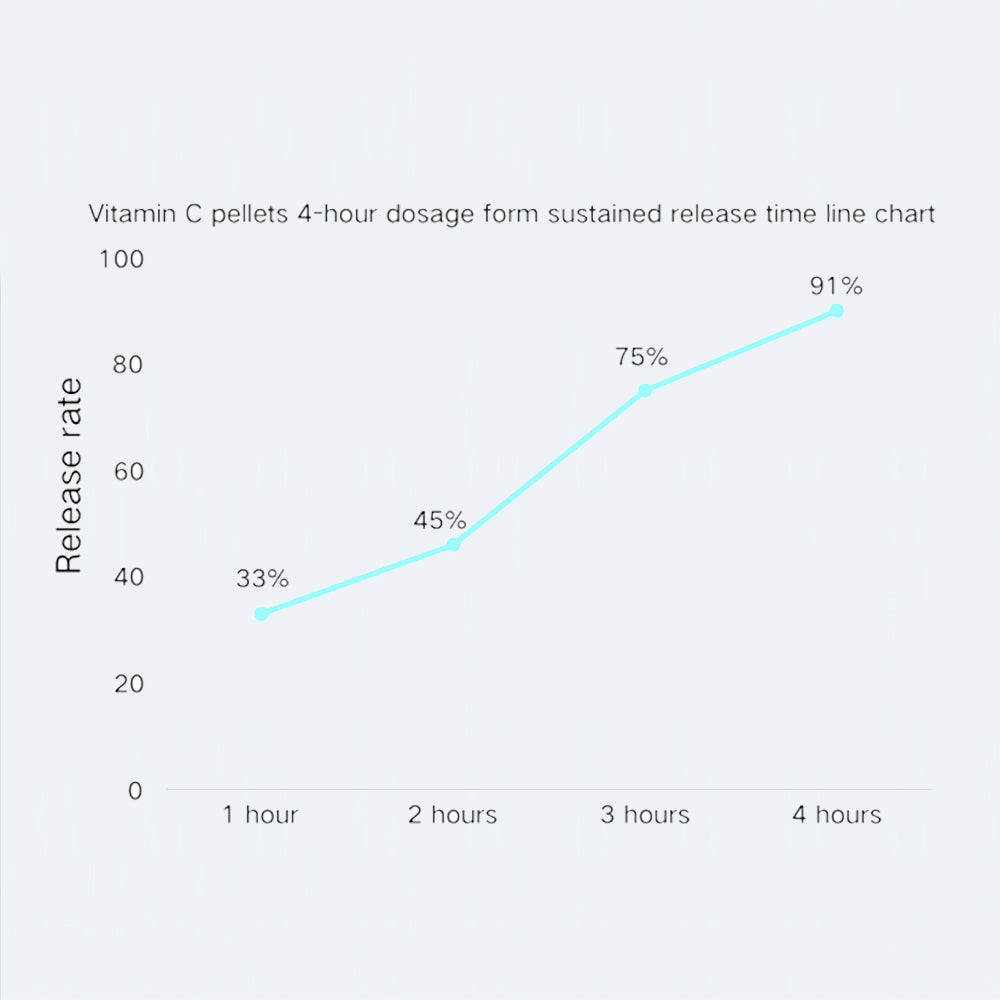

Sustained release testing

According to the Chinese national standard sustained-release in vitro testing method, we used the paddle method to conduct in vitro testing of the sustained-release time of the pellets.

Put 100 mg sustained-release pellets into 250 ml of water, stir the pellets at 50 rpm/M in constant-temperature water with a pH of 7 at 37°C ± 1°C, and use HPLC to detect the content of active substances in the solution every hour to obtain its slow release curve.

We generally believe that a 4-hour sustained-release dosage form should release less than 40% at 2 hours, and more than 90% after 4 hours is qualified. An 8-hour sustained-release dosage form should release less than 50% at 4 hours, and exceed 90% after 8 hours is qualified.

Pellet customize process

-

Confirm formula ingredients and content

Determine whether the pellets you want to customize are sustained-release, your desired sustained-release time, color, smell and most importantly, what active ingredients should be in them, and then we will give you a quote.

-

Production samples

According to your request in the first step, we will make samples for you, and a third-party testing agency will test the sustained release time and the content of active ingredients in the pellets, issue a third-party report, and we will send the samples to you.

-

Bulk production

According to the standard of the samples, we carry out mass production, and after the production is completed and before shipment, we will conduct sampling testing of the goods. They will also be tested by a third-party testing agency and issue an authoritative testing report. MOQ is only 50kg.